The Brewers of Pennsylvania are hosting the 8th Annual Mid-Atlantic Brewers’ Symposium & Expo from October 23-25, 2022, at the Toftrees Resort & Conference Center in State College, PA. This two-day event will focus on the science and business aspects of brewing, exposing attendees to valuable industry resources and insights to help them navigate Pennsylvania’s continually evolving craft beer landscape. The two-day symposium will feature thirteen 45-minute general sessions, multiple breakout sessions, a welcome reception with 30+ industry exhibitors, and a lively social event.

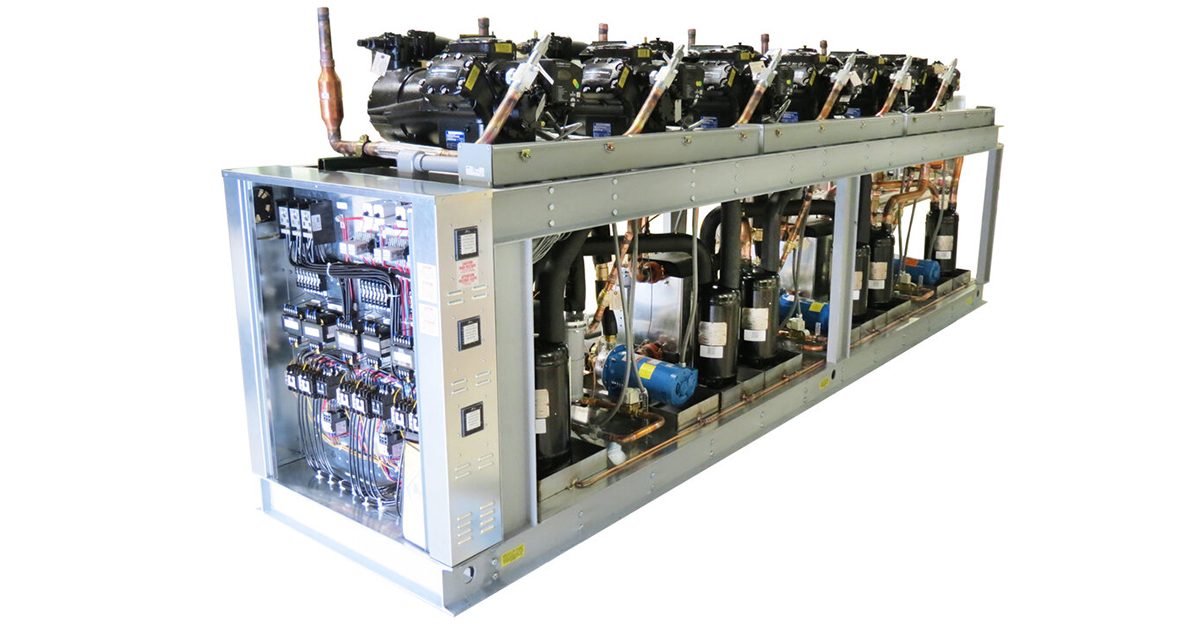

As a proud exhibitor at this year’s expo, we are one of the industry resources you can meet at this exceptional event. We’ll be there to provide helpful advice for optimizing your brewing operation with high-performance industrial-grade brewery chillers designed to keep your brewing processes cool for more uptime and higher-quality brew.

If you’re not planning to attend the show, this preview will give a glimpse into the latest brewery chiller innovations to consider.

First, let’s review the basics of brewery chillers to demonstrate their role and importance for a growing brewing business.

Brewery chiller basics

Industrial-grade brewery chillers use process cooling to remove heat from your brewing equipment, helping it to operate smoothly and efficiently. They’re suited for many brewing processes, including wort cooling, Brite tank temperature control, fermentation temperature control, crash cooling, pre-packaging, and product storage.

Brewery chillers differ from off-the-shelf comfort chillers, offering many functional benefits that can enhance production efficiency and the quality of your beer.

These benefits include:

- Heavier duty performance to keep up with your rugged brewing processes

- Tighter temperature control to maximize your equipment efficiency and brew’s taste

- Year-round performance to keep your operation on track regardless of the season

- More accurate refrigeration technology when you work with specialized experts who have mastered the art of brewery process cooling

A preview of our brewery chiller exhibit & insights

Drake’s Engineering Manager, Shane O’Donnell and Scott Noyes from our Sales Team will be on hand at the 2022 Mid-Atlantic Brewers Symposium & Expo to discuss high-performance solutions designed for breweries and provide helpful insights about:

- Air- versus water-cooled brewery process chillers, and which system makes the most sense for your operation

- Remote condenser systems for brewing facilities that require the condenser to be separate from the evaporator

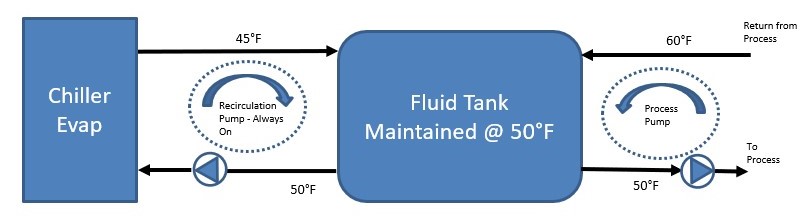

- Whether you need a tank and pump package and how to select the ideal configuration

- Factors that affect which size brewery chiller you need, such as your brewery’s beer volume, pull-down/crashing loads, active fermentation heat load, wort heat exchanger secondary heat load, Brite tank holding load, and heat gain compensation

- Which customizations and options to consider for enhancing the performance, usability, and energy efficiency, including redundancy options, custom controls, and high-efficiency options

- How to configure a scalable brewery chiller system that will grow along with your operation, whether you have one or 100 pieces of equipment

- How high-performance industrial-grade chillers can enhance many aspects of your brewing business as they did for Chestnut Hill Brewing Co.

There’s much more to discover at the show! We hope to see you there.

Your industry-leading brewery chiller experts

With more than 50 years of heavy-duty process cooling experience, we’re uniquely qualified to produce the right chiller solution for brewers who demand as much from their equipment as they do their brew. While some companies offer a hodgepodge of brewing equipment, we only focus on the chiller, helping to ensure your brewery chiller’s refrigeration technology is tailored for your one-of-a-kind application. With a proven 99%+ uptime rate and exceptional after-the-sale tech support, trust our brewery process chilling expertise to keep your operation online 24/7. Contact us or request a quote to learn more.