While industrial chiller storage and recirculation tanks may appear similar on the surface, they have distinct operational differences that can dramatically affect your process chiller’s performance. In this decision guide, we’ll cover the benefits and considerations for storage and recirculation tanks, clearly teasing out the bottom line to help you determine the best option for your needs.

Storage tanks

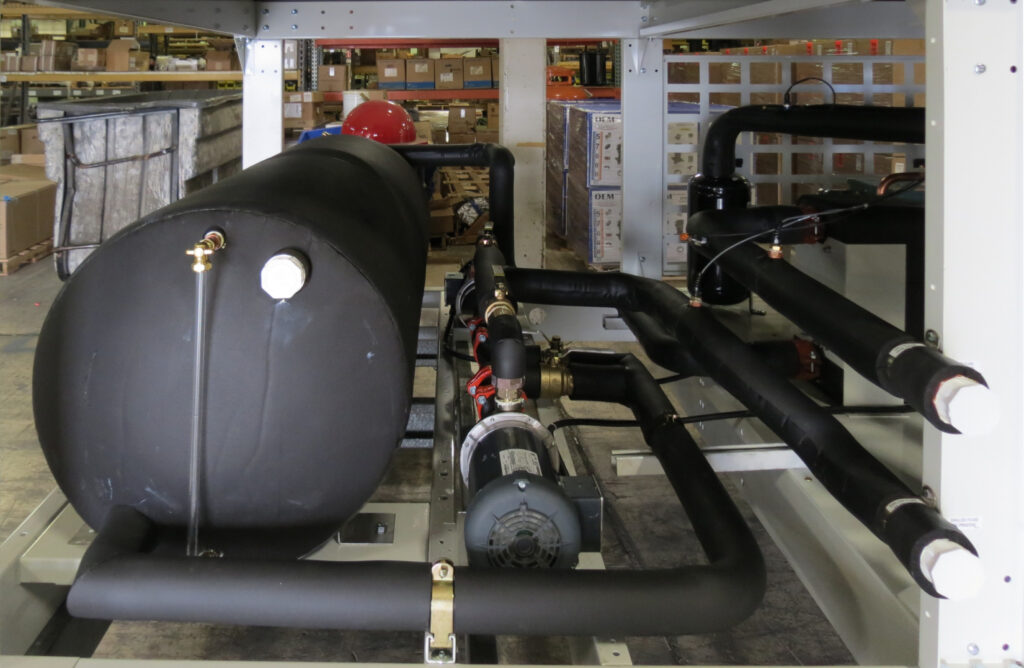

Storage tanks help add volume to a chiller system, which helps prevent short-cycling. They contain a single pump and are available in stainless steel or polyethylene and can hold between 30 to 30,000+ gallons. While they cost less than recirculation tanks, storage tanks cannot hold the cooled fluid temperature when the process is off. They also do not absorb process variations, such as load, flow rate, and return temperature. For instance, when the flow rate reduces, the leaving fluid temperature (LFT) also reduces, posing the risk of freezing.

Benefits of storage tanks:

- Adds fluid volume to the chiller system to help prevent short cycling

- Contains a single pump

- Costs less than a recirculation pump

Considerations for storage tanks:

- Does not hold temperature

- Does not absorb process variations, such as load, flow rate, and return temperature

- Glycol does not stay cold when your process is off

The bottom line

Choose a storage tank when you need to add fluid volume to prevent short-cycling, but do not need it to hold temperature, absorb process variations, or maintain cold glycol when your process is not running.

Recirculation tanks

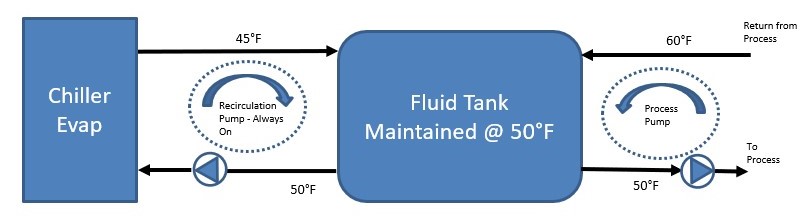

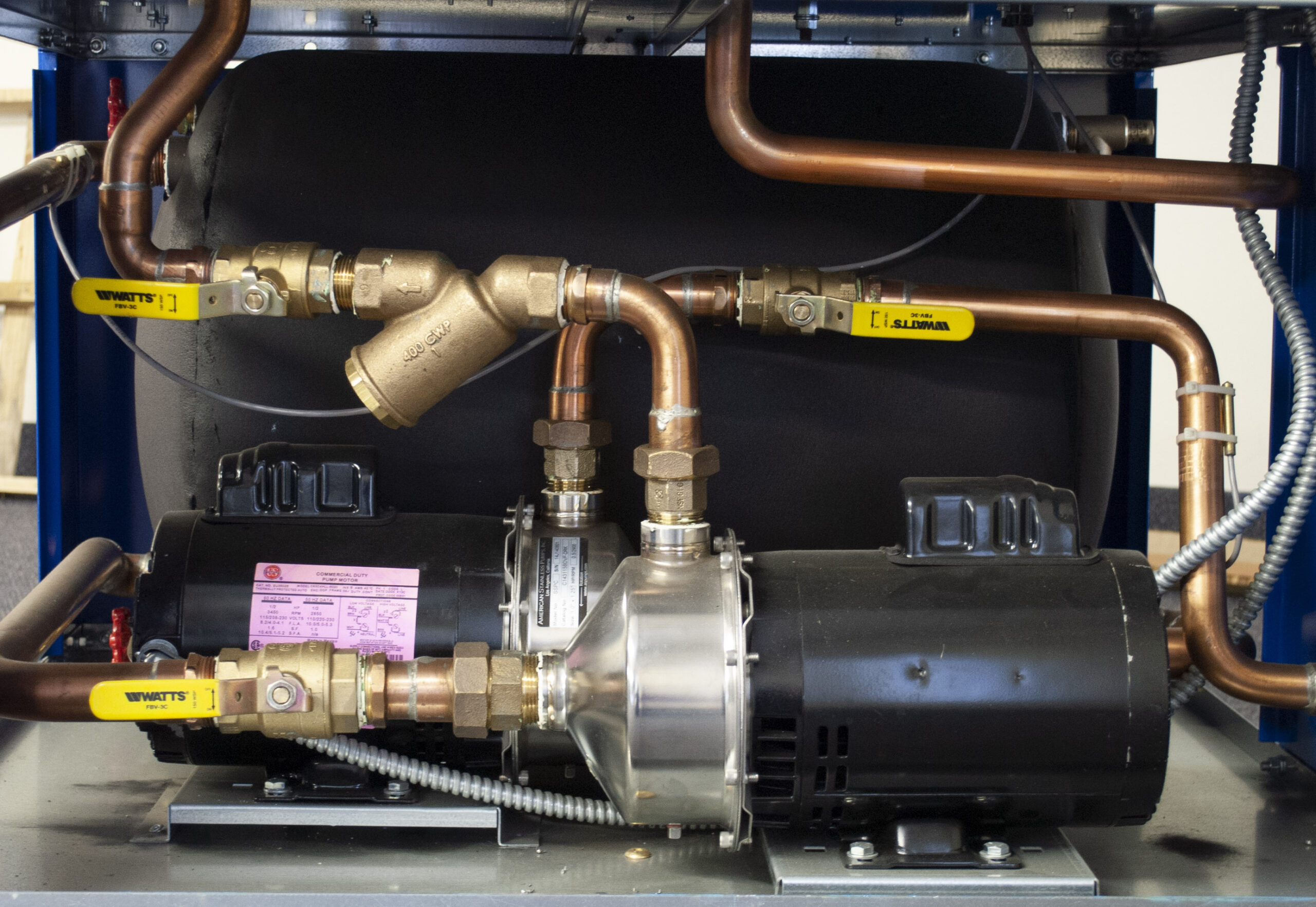

By its very definition, process chilling is marked by tight temperature controls and varying flow rates or demands in varying conditions. As such, recirculation tanks are often required to achieve these goals. Recirculation tanks are a two-pump, dual-loop system that isolates the process flow from the evaporator flow. They can be on-board a chiller, a stand-alone unit, or have a separate tank section. Like storage tanks, recirculation tanks are available in both steel and polyethylene and 30 to 30,000+ gallon capacities. The primary advantages include tight temperature control within +/- 1° F, and glycol tanks stay cold, even when your process stops running. Additionally, recirculation tanks absorb process variations, such as heat load, flow rate, return temperatures, process on and off, etc. These tanks are more expensive than storage tanks because of the second pump. It’s also important to note that an upsized chiller may be necessary because the chiller evaporator to tank (recirculation) line is always 5° F colder than the tank/process temperature. Learn more about our industrial process chillers on our product overview page.

Benefits of recirculation tanks:

- Holds temperatures +/- 1° F

- The two-pump, dual-loop system isolates process flow from evaporator flow

- Evaporator only detects the constant recirculation pump flow

- Absorbs process variations, such as heat load, flow rate, return temperatures, etc.

- Glycol tank stays cold, even when your process is not running

Considerations for recirculation tanks:

- The addition of a second pump makes recirculation tanks more expensive than storage tank

- May need to upsize your chiller to account for 5° F difference between evaporator to fluid tank line and fluid tank to your process

The bottom line

Choose a recirculation tank when you need tight temperature control, process variation absorption, and the glycol tank to remain cold when your process is not running.

Would you like to learn more about whether you need a storage or recirculation tank? Contact our team to learn more about the features and benefits of these two options. We have over 40 years of process chiller experience and provide a robust line of engineered solutions with cooling capacities ranging from ¼ to 200 tons. We have many systems available to ship quickly, and every chiller comes with our excellent after-the-sale service and support.