Industrial chillers are heat exchangers that remove process heat to keep brewing, dairy, food processing, medical, low-temp, and other industrial equipment running smoothly. While our high-quality engineered solutions are designed for optimal performance, adhering to a routine preventative chiller maintenance schedule is critical to your system’s longevity and efficiency. In this article, we’ll cover the basics of chiller maintenance, highlighting frequency recommendations, and providing additional hints for monitoring chiller performance.

Quarterly and annual preventative chiller maintenance checklists

Whether your facility has an industrial process chiller or is in the market for one, the following chiller maintenance checklists contain the basic quarterly and annual tasks your technician should know. Completing them at the designated interval can help maximize your system’s performance and extend its lifespan.

Quarterly chiller maintenance checklist:

- Review chiller logs (learn more about how to create daily chiller logs below)

- Check oil filters

- Check Y-strainers

- Check pump gaskets and seals

- Check for leaks

- Tighten all electrical components

- Check overloads

- Check contractors

- Check variable frequency drives (VFDs), if applicable

- Check overall chiller operation, looking for odd noises or faulty performance

Annual chiller maintenance checklist:

- Clean condenser coils-fin

- Flush evaporator

- Flush condenser-coaxial

- Test compressor oil

- Change oil filters

Refer to your Drake chiller model’s Installation, Operation, and Maintenance Manual on our Tech Support page for a PDF checklist of these tasks. Whether you use our chiller maintenance checklist or create your own, include the following information for your records:

- Type of preventative chiller maintenance (i.e., quarterly vs. annual)

- Site or building name

- Technician’s name

- Date

- Chiller model number

- Chiller serial number

How to create a daily chiller maintenance log

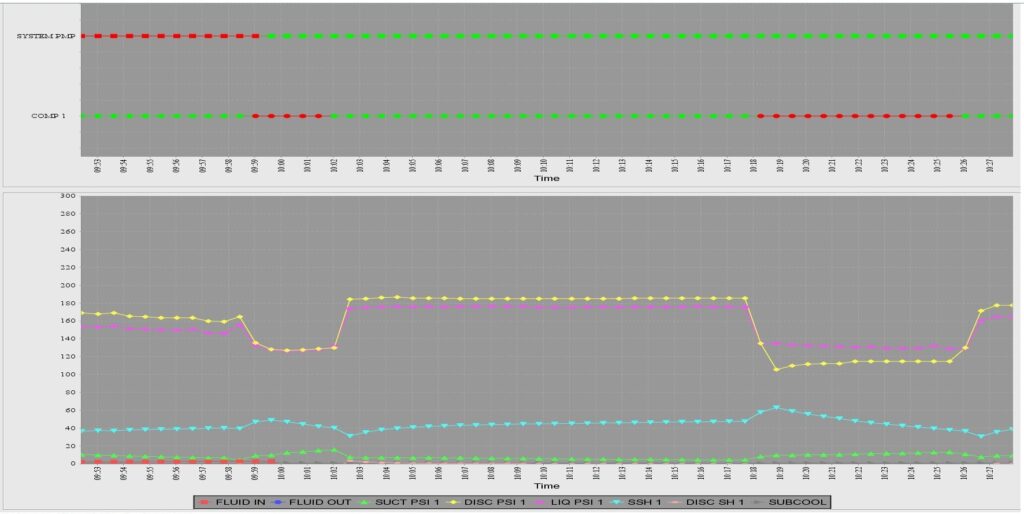

Between quarterly and annual preventative chiller maintenance, record operational data in a daily operating log. Observe overall performance, pressure, temperatures, fluid levels, and flow rates. Building a history of your industrial process chiller in this way makes it easier to identify and correct issues before they arise, helping to minimize downtime and reduce costly repairs. If a problem does occur, a daily chiller maintenance log can help technicians quickly and efficiently pinpoint the source of the problem.

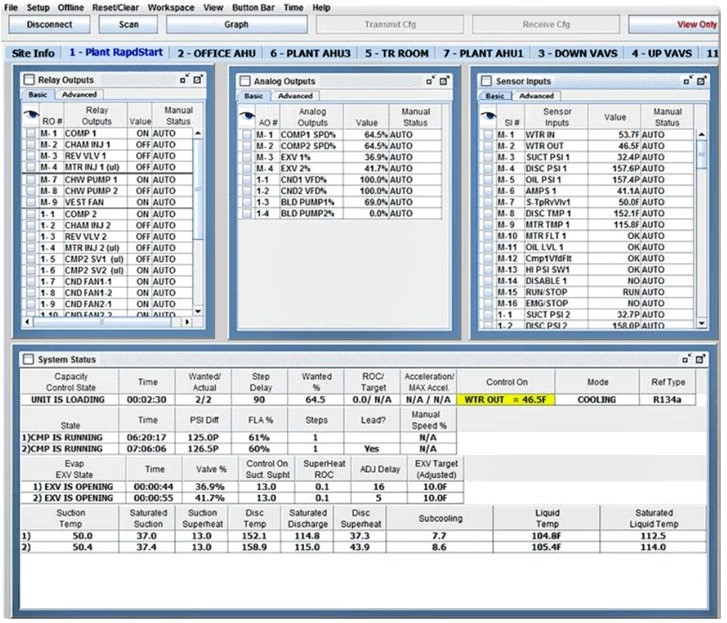

Keep the daily chiller maintenance logs in a centralized location or enter the operational data into a web-based chiller efficiency software program. These tools can measure chiller performance at full or partial loads, calculate system efficiency, and help diagnose the causes of any identified inefficiencies.

Control technologies for monitoring chiller performance

While routine system checks and daily logs are essential, advanced technologies can help you keep an even closer eye on your chiller’s real-time performance, especially when you have multiple units. A couple of optional controls that make chiller monitoring easier include:

- MCS Micro-controllers – Similar to a smart home technology system, an MCS micro-controller allows you to monitor and adjust your chiller maintenance settings from an on-board or remote touchscreen, allowing for tighter process control.

- Chiller Guard – A feature we can custom program to send an email or text message to you in case of an alarm, Chiller Guard offers a convenient way to monitor your chiller’s performance from afar.

Because we offer engineered solutions, we can program specific controls to meet your unique needs and budget. Customizing a chiller with controls ensures that monitoring performance is convenient and easy, adding yet another layer of protective oversight to your chiller maintenance protocol.

Are you interested in learning more about chiller maintenance? Contact our team to discover how to optimize the performance of a Drake industrial process chiller. With over 40 years of industry experience, we provide the highest quality and durable chillers with cooling capacities ranging from ¼ to 200 tons.