Many companies opt for packaged water-cooled chillers because they are quick to install, long-lasting, quiet, and energy-efficient. They’re found in many industrial applications, such as food processing and manufacturing. These highly efficient chillers use water from an external cooling tower to remove process heat from the condenser.

Situated between the compressor and expansion valve, water-cooled condensers function as a specialized heat exchanger that condenses the hot pressurized gas from the compressor into a liquid. In this article, we’re covering the three primary types of condensers we use in packaged water-cooled chillers.

- Shell-and-tube

- Coaxial tube-in-tube

- Brazed plate

Shell-and-tube condenser

Shell-and-tube is one type of condenser in packaged water-cooled chillers. This highly efficient water-cooled design features straight water tubes enclosed in a cylindrical shell. Grooved tube sheets are welded on both ends of the cylinder, and the water tubes are positioned to allow for a vapor-tight fit. The cooling process starts when the hot refrigerant is released from the compressor and enters the top of the cylindrical shell. Once it makes contact with the water tubes, the vapor-to-liquid conversion process begins. The final cooling phase of packaged water-cooled chillers with shell-and-tube condensers is when newly condensed liquid refrigerant releases through the bottom of the cylindrical shell and travels to the expansion valve.

Features and benefits of shell-and-tube water-cooled condensers:

- Highly efficient water-cooled design

- Easy to clean and repair

- Economical

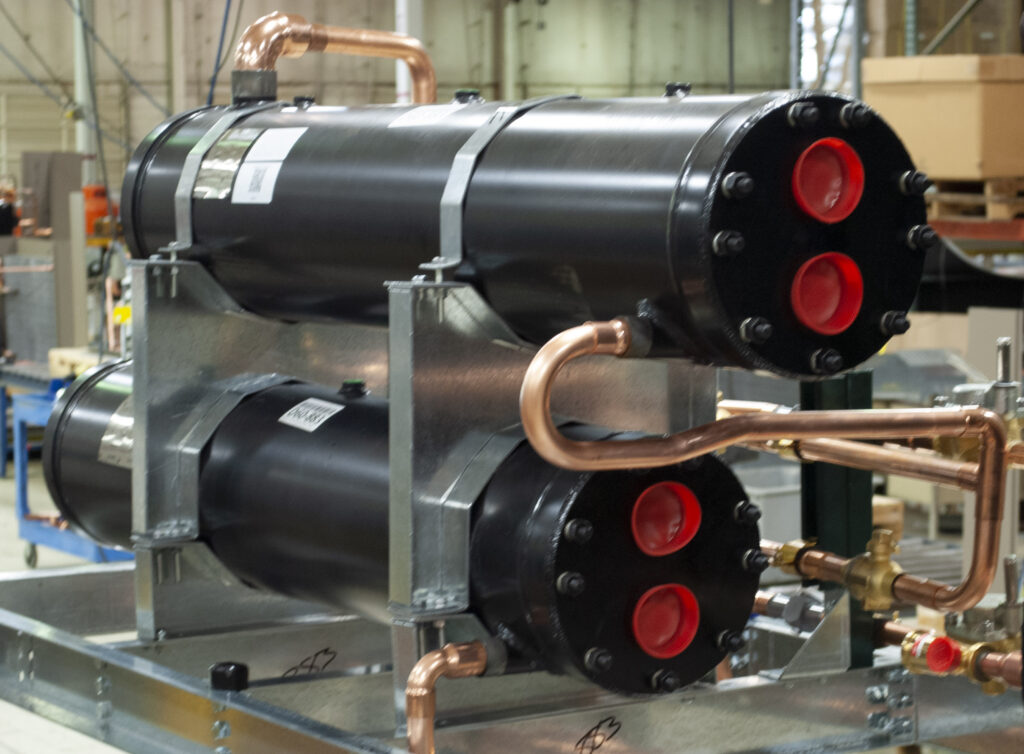

Coaxial tube-in-tube condenser

Another commonly used condenser in packaged water-cooled chillers is coaxial tube-in-tube. These highly effective and compact heat exchangers may be best known for their superior anti-fouling characteristics. Using two nested tubes, the water passing through the inside tube cools the refrigerant in the outside tube. These water-cooled condensers have a counter-flow construction where the cooling water flows in the opposite, or counter, direction to the refrigerant. The coaxial tube-in-tube water-cooled condenser design ensures that the coldest water makes contact with the coldest refrigerant to provide the highest mean temperature differential and heat transfer rate.

Features and benefits of coaxial tube-in-tube water-cooled condensers:

- Highly effective, compact heat exchanger

- Superior anti-fouling characteristics

- Counter-flow construction

Brazed plate condenser

Brazed plate is the third and final type of condenser we use in packaged water-cooled chillers. This condenser is corrosion-resistant, cleanable, and provides enhanced heat transfer. Its constructed of a series of metal plates held together with a copper-based brazing material, lending a non-ferrous construction that eliminates rusting and corrosion. The embossed pattern of the plates creates a channel for fluids to flow and allow for highly efficient heat transfer between the process water and refrigerant water. This condenser design for water-cooled chillers allows cold fluid to make contact on one side and hot on the other side.

Features and benefits of brazed plate water-cooled condensers:

- Corrosion-resistant

- Cleanable

- Enhanced heat transfer

Types of packaged water-cooled chillers

Our single and dual packaged water-cooled chillers include in-stock and custom-ready engineered solutions, depending on your application and budget.

- Fractional hermetic single circuit chillers

- Scroll single circuit chillers

- Scroll dual circuit chiller

- Digital scroll single circuit chillers

- Digital scroll dual circuit chillers

- Semi-hermetic single circuit chillers

- Semi-hermetic dual-circuit chillers

- Screw dual circuit chillers

- Tandem scroll chiller

Condensers are just one essential component of industrial process chillers. The evaporator, compressor, and expansion valve play equally vital roles in an efficient cooling process. Read more about the main components of a process chiller on our blog.

If you’re interested in learning more about the types of condensers used in our packaged water-cooled chillers, request a quote online, email us, or call (888) 289-7299 today.