There are many types of chillers, each with a specific configuration and capabilities. So, which one is best? In short, the best chiller for you will depend on several factors, including:

- Your budget

- Your application and environment

- Your preferences

In this post, we’ve compiled several common scenarios related to these factors and suggested the best chillers to consider for each one. The result? An easier – and smarter – decision process.

Best chillers for: Year-round operation

If you’re in the medical, dairy, food processing, manufacturing, or similar industry that requires all-season performance, industrial process chillers are the best solution for you. As opposed to standard comfort chillers that can develop refrigeration issues in the winter, industrial-grade chillers will keep your equipment cool all year-round.

Best chillers for: Tight temperature control

Besides year-round operation, many industrial applications have strict temperature requirements to keep the equipment running strong. In this scenario, go with an industrial process chiller over a standard comfort chiller for the best results. With the help of variable frequency drives (VFDs) and recirculation tanks, our product line of industrial process chillers maintain temperature control of +/- 1°F.

Best chillers for: Minimum installation costs

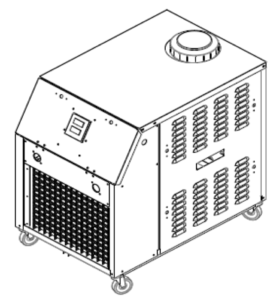

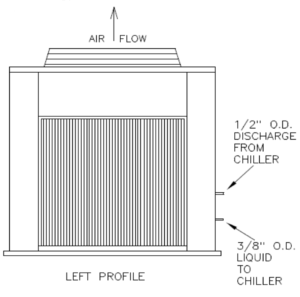

If budget is a concerning factor, packaged air-cooled chillers may be the best option for you. These quick-to-install systems include just a few components: a condenser, compressor, and evaporator. Without a cooling tower, condenser pump, and other parts required for water-cooled alternatives, installation teams spend less time installing, saving you upfront costs.

Best chillers for: Energy efficiency

Energy efficiency is becoming increasingly relevant for saving costs and preserving resources. The tricky part here is that both air-cooled and water-cooled chillers have energy-efficiency features, making it critical to closely weigh the options with a seasoned chiller expert.

Best chillers for: Limited interior space

Is your indoor environment short on space? In that case, a packaged air-cooled chiller might be the best solution. These space-saving systems are housed outdoors rather than indoors and don’t require square footage for cooling towers, condenser pumps, or mechanical rooms.

Best chillers for: Longevity

If you’re looking for a chiller that can stand the test of time, a packaged water-cooled chiller might be the best option for you. As opposed to outdoor air-cooled units, water-cooled chillers remain indoors, protected from harsh outdoor elements that can shorten the system’s lifespan.

Best chillers for: Water-sensitive environments

If you’re in a drought-prone area or have limited access to a continual water source, your best bet is a water-saving air-cooled chiller. These units are designed to cool your industrial processes using ambient air – not water.

Best chillers for: Low-temperature requirements

If you’re in aerospace, food processing, automotive manufacturing, cannabis extraction, ice rink operation, or another industry with intense chilling needs, a low-temp chiller is the best choice for you. These systems include both air- and water-cooled units with oil management and other low-temp options to ensure your fluids remain ultra-cool.

Best chillers for: Noise-sensitive environments

Water-cooled chillers best serve hospitals and other noise-sensitive environments. In contrast to air-cooled chillers that use sound-producing cooling fans, water-cooled alternatives use quiet-flowing water to keep your processes cool.

Best chillers for: Humid environments

The moisture in your environment plays a significant role in determining the best type of chiller. Water-cooled chillers may add to the moisture levels in humid environments, making air-cooled systems the best solution for this scenario.

Best chillers for: Environments incompatible with packaged chillers

If your environment lacks a continual water source, is humid, and has poor ventilation, neither a packaged air- or water-cooled chiller is suitable. In this scenario, the best option is a split system chiller with two distinct sections installed in different places – one outdoors and the other indoors.

Whether your chiller needs match these scenarios or require something else entirely, we invite you to partner with us. We customize our robust engineered solutions to satisfy any requirement. We back up our products with exceptional after-the-sale support and a 99.4% uptime rate. Reach out to our team online or call (888) 289-7299 to discover the best chillers for you.