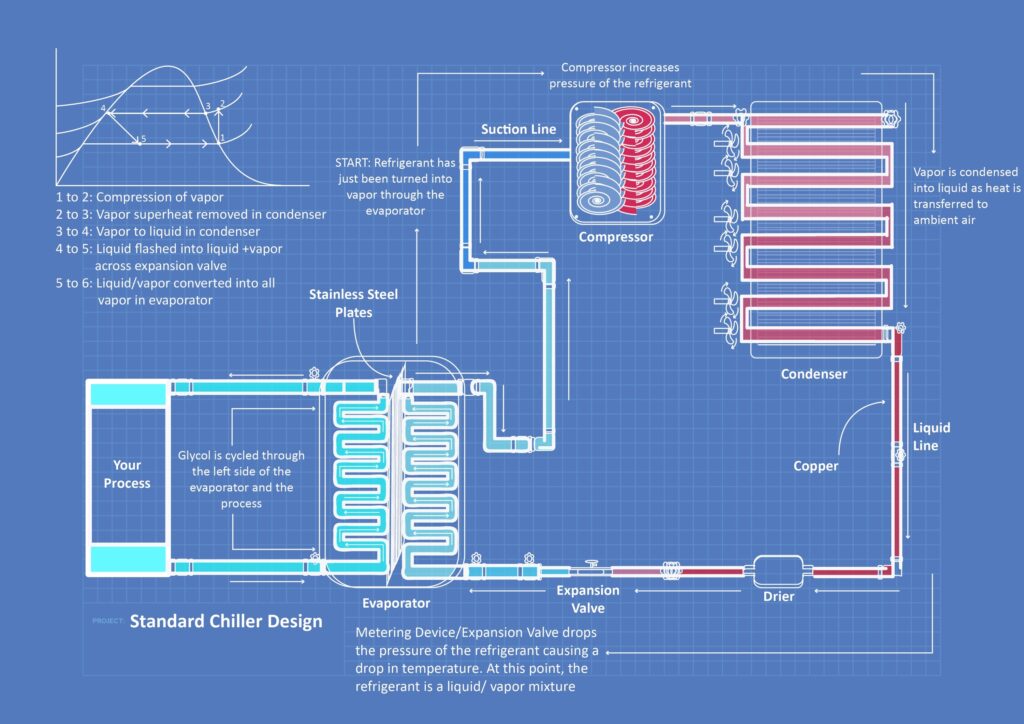

Whether air- or water-cooled, industrial chillers work the same way as other refrigeration systems built into your home, refrigerator, and car. However, instead of keeping your environment and food cool, they chill water or glycol to keep your industrial processes cool. The cooling effect works by cycling refrigerant through the chiller system, with various temperature and pressure changes happening at every stage. In this article, we’ll review the components of chillers and outline the unique role they play during each of the five cooling phases.

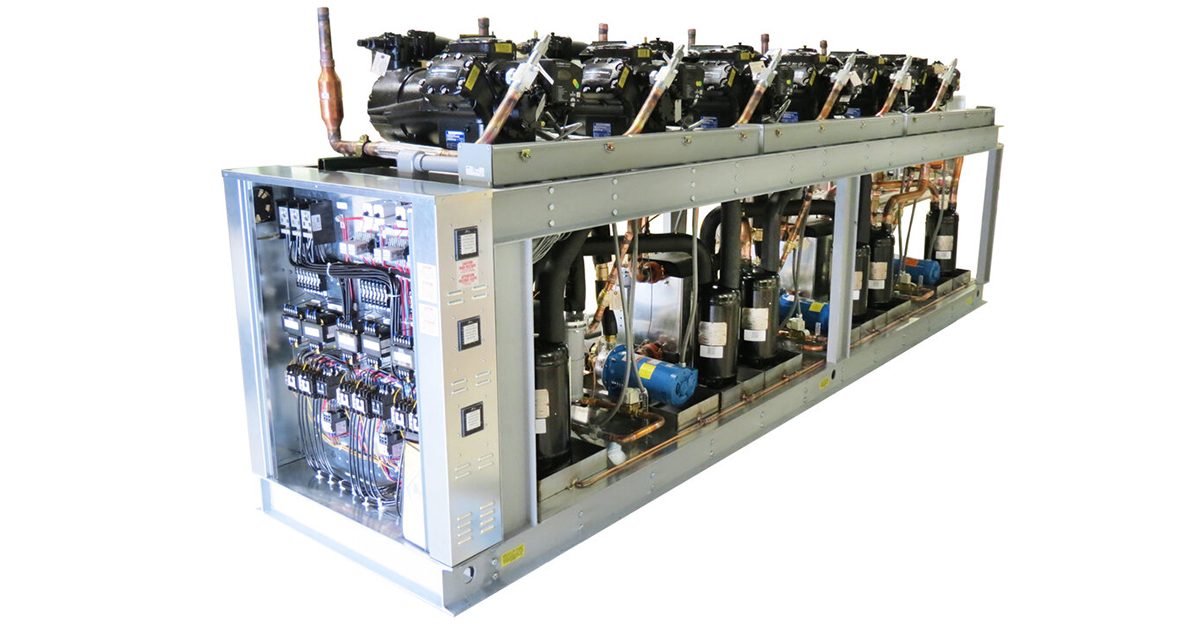

The components of chillers

As we covered in our previous blog article, the following are the main components of process chillers and how they contribute to the cooling process:

- Evaporator – Available in coil, shell and tube, and plate, a chiller evaporator’s role is to absorb heat when water from your industrial processes enters this component. This process heat boils the refrigerant in the evaporator, converting it from a low-pressure liquid to a low-pressure gas, or superheated vapor.

- Compressor – Chiller compressors come in scroll, screw, and semi-hermetic options in a range of horsepower to suit your application. The compressor takes the low pressure vapor from the evaporator and converts it into a high-pressure gas.

- Condenser – Situated between the compressor and expansion valve, chillers are configured with an air-cooled, water-cooled, or split-system condensing unit, depending on your application environment. These components are a heat exchanger that condenses hot, high-pressure gas from the compressor into a liquid using either water or ambient air.

- Expansion valve – Whether a thermal expansion valve, thermostatic expansion valve, or an electronic expansion valve, each type controls the refrigerant passing between the condenser and evaporator, varying the flow based on the cooling load changes.

Beyond these main components of chillers, the industrial cooling process also uses many secondary components, including

- Suction accumulator – Prevents liquid refrigerant flood back to the compressor

- Liquid line Solenoid – Valve with a magnetic coil the opens and closes during an active refrigeration cycle

- Filter Drier – Filters and dries the refrigerant

- Fluid flow switch– Flow sensing device to ensure enough fluid is moving across the evaporator to boil the refrigerant

Next, let’s look at which of these chiller components are at work during each of the five phases of the cooling process.

How chiller components work throughout the cooling process

Phase 1: Vapor superheat removal in the evaporator

The cooling process starts at the evaporator, where the refrigerant is converted into vapor. The vapor travels through the suction line and into the compressor.

The primary chiller components at work during this phase include:

- Evaporator

- Suction line

- Compressor

Phase 2: Vapor compression in the compressor

The second phase is all about the compressor, when it takes the vapor from the evaporator, increases the pressure of the refrigerant, and transforms it into a high-pressure gas.

The primary chiller component at work during this phase is: the compressor.

Phase 3: Vapor converts to liquid in the condenser

The third phase of the industrial cooling process is when the condenser condenses the vapor into liquid and travels down the liquid line and through the drier.

The primary chiller components at work during this phase include:

- Condenser

- Liquid line

- Filter Drier

Phase 4: Liquid flashed into liquid & vapor across the expansion valve

The fourth phase involves the expansion valve, a metering device. This chiller component drops the refrigerant pressure, triggering a drop in temperature. Now, the refrigerant is a liquid/vapor mixture on its way back to the evaporator.

The primary chiller component at work during this phase is: the expansion valve.

Phase 5: Liquid/vapor converted into all vapor in the evaporator

Finally, the liquid/vapor mixture converts into all vapor in the place where the chilling process began – the evaporator.

The primary chiller components at work during this phase is: the evaporator.

As we’ve highlighted in this article, every component of chillers has an important role in cooling your industrial processes. For more on how process chillers work, check out the article on our blog. You can also check out an illustrative perspective of the cooling process on our website.

With over 40 years of experience designing and manufacturing industrial process chillers, we’re your source for high-performance systems with an excellent uptime rate and after-the-sale support. To learn more, request a quote online,email us, or call (888) 289-7299.