If you’re looking for a brewery chiller, there are several factors to consider, each one critical for choosing the best option for your budget, operation, and goals. You may have caught a few of them in our previous blog post on what to look for in a chiller. That article outlined the importance of features, such as industrial-grade performance, consistent temperature control, year-round operation, capacity modulation, customizable controls, and energy efficiency options.

If you’re looking to explore more about brewery chiller selection beyond these essentials, this post is for you. In it, we’ll explore six additional considerations to factor into your chiller selection decision, including:

- Chiller size

- Expansion plans

- Redundancy

- Temperature sensitivity

- Unit location

- Building requirements

Keep reading to dive deeper into what you need to know about brewery chiller selection.

Chiller size

Selecting the right brewery chiller size is a bit like the children’s story, Goldilocks and the Three Bears – it’s essential to choose just the right size for your needs. The appropriate size will not be too small because then you wouldn’t achieve the desired glycol temperatures to keep your brewing processes cool. On the other hand, it won’t be too large, either, because you wouldn’t meet the desired refrigerant requirements. It turns out that the best option is to go with a Goldilocks “just right” size – one that’s not too small nor too large.

Expansion plans

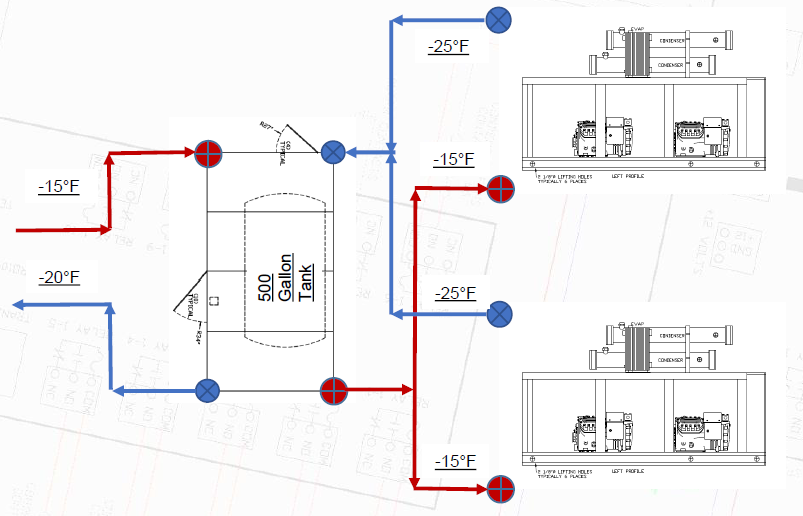

If you’re planning to expand your brewing operations in the foreseeable future, make room for this anticipated growth in your chiller selection. Knowing about any expansion plans from the get-go will help ensure that your system installation includes additional refrigeration circuits to accommodate your growing operation. Plans for expansion also dictate whether you’ll need higher glycol volume with a larger tank.

Redundancy

The next factor to consider when selecting your brewery chiller is redundancy, or a system backup. Redundancy options include a redundant refrigeration circuit or redundant chillers, depending on your brewery’s specific application environment and requirements.

Temperature sensitivity

Next up in our list of factors to consider in your chiller selection is temperature sensitivity. How sensitive to fluctuations in fluid temperature do you want your brewery chiller to be? For ultimate temperature control, consider on-demand cooling tanks with dual-loop recirculation to maintain consistent glycol temperatures in virtually any condition. Many brewers love the tight temperature control advantages of a chiller versus a comfort cooler because it allows your brew to taste its best with every batch.

Unit location

Brewery chillers provide flexible installation options that allow you to install them indoors or outdoors, depending on whether you choose a packaged air-cooled or water-cooled system. If your location cannot accommodate a packaged unit because the environment has high humidity, low ventilation, and no continual water source, then your brewery chiller selection may involve a split system configuration. These specialized air-cooled units feature two sections, where one set of components is installed indoors, and the other is outdoors.

Building requirements

The final factor for chiller selection is all about your brewery’s building requirements. Check to see whether the system must comply with specific power or unit size constraints to ensure you select the best option for the designated building codes.

Head to our website to learn more about our robust lineup of custom-ready, high-performance brewery chillers. There, you’ll find everything you need to know about selecting the best system for your needs. You can even download a real-life example of how we helped Chestnut Hill Brewing Co. find the best match.

With a proven 99%+ uptime rate, brewer-centric customizations, and cost-effective and quick-ship options, we are your source for brewery chillers designed to help you elevate your craft. In addition, our excellent after-the-sale support provides peace of mind that we have your back. Contact us to request a quote or reach out to let us help make your chiller selection process easier.