An industrial chiller uses process cooling to divert heat away from industrial equipment, helping to keep processes cool and machines operating efficiently. Depending on your budget, environmental conditions, preferences, and other factors, they use either ambient air or water to remove heat from your industrial processes. Chillers are essential components for many industries, including brewing, dairy, food processing, medical, cannabis, and other industrial applications.

In this post, we’re taking a deep dive into the world of chillers to reveal more about what they are and how they work.

Types of industrial chillers

Which type of chiller is right for you? Compare the features of air- vs. water-cooled chillers below.

Air-cooled chillers

Air-cooled chillers use ambient air to remove heat from industrial processes. These cost-effective packaged units set up quickly and have fewer components, saving on installation and maintenance costs. Air-cooled chillers are ideal for environments with limited interior space because they’re housed outdoors. However, they can be loud, and the exterior conditions may shorten their lifespan.

- Ambient air removes process heat

- Cost-effective

- Quick installation

- Low maintenance

- Space-saving

- Can be noisy

- Shorter lifespan

Water-cooled chillers

The process cooling action of water-cooled chillers relies on a continual water source from an external cooling tower. The chiller remains indoors, helping to extend the lifespan of these packaged units. These chillers operate quietly and feature energy-efficiency features but require more maintenance and are more expensive than air-cooled alternatives.

- Water removes process heat

- Longer lifespan

- Quiet operation

- Energy-efficient

- Requires more maintenance

- More expensive than air-cooled chillers

Split system chillers

Split system chillers offer an alternative for circumstances where neither a packaged air- nor water-cooled chiller will suffice. For instance, your environment lacks access to a continual water source or has high humidity levels that prohibit a water-cooled chiller and has poor ventilation that renders an air-cooled alternative unsuitable. In this case, consider a split system chiller, where the evaporator and compressor are installed indoors, and the condenser is installed outdoors to maximize ventilation.

Ever wondered how chillers work? Continue reading the next section to discover what you need to know about refrigeration basics.

How chillers work

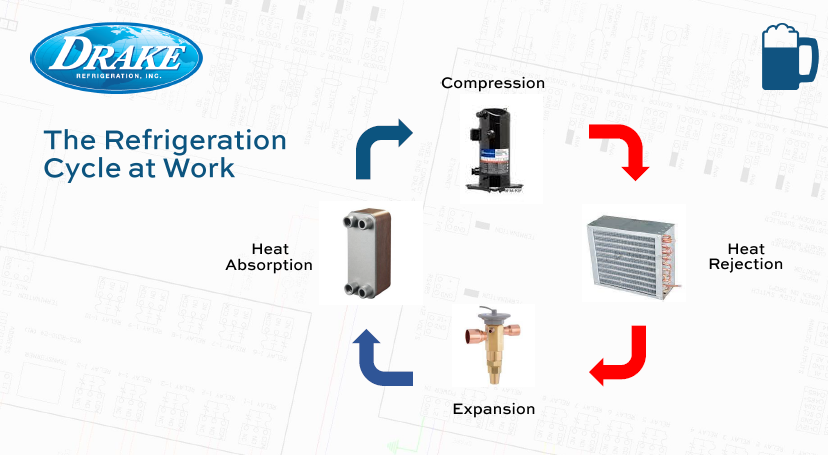

Chillers contain four essential components, each integral in the refrigeration process. Here’s how these systems work:

- Evaporator – Absorbs process heat and initiates the refrigeration process

- Compressor – Compresses the vapor from the evaporator and converts it to a high-pressure gas

- Condenser – Condenses the high-pressure gas into a liquid

- Expansion valve – Controls the refrigerant flow based on the heat load

How can you benefit from industrial process chillers? Continue reading to explore the top ten benefits of these high-performance systems.

10 Benefits of industrial chillers

Industrial-grade chillers are advantageous because they:

- Operate year-round

- Offer tight temperature control

- Stand up to rugged application environments

- Help increase equipment uptime

- Are energy-efficient

- Can withstand low-temperature requirements

- Are safe for food applications

- Allow you to customize the features

- Can accommodate multiple pieces of equipment

- Are okay to use in corrosive environments

Continuing our exploration of chillers, the next section outlines the must-know fluids for all-season performance.

Types of chiller fluids to consider

If you’re planning to operate your industrial chiller year-round, consider the following chiller fluids to keep your chiller and equipment going strong:

- Propylene glycol and water mixture (10-60%)

- Ethylene glycol and water mixture (10-60%)

- Dynalene HC-10 to HC-50

- Calcium chloride solution

Head to our blog to learn more about chiller fluids for year-round operation.

When you’re looking for a high-performance industrial chiller, browse our robust lineup of custom-ready units. We have a proven 99%+ uptime rate, an array of customization options, cost-effective solutions, quick-ship options, and excellent after-the-sale support. We are your trusted source for industrial chillers designed for lasting performance. Request a quote or reach out to our knowledgeable chiller team to learn more.