With more people choosing to eat at home during the pandemic, the demand for frozen food skyrocketed. Enhanced availability and food quality also contributed to the increased trend that experts believe is here to stay, leading many suppliers to upgrade and expand their cold storage solutions. If you’re considering upgrading an off-the-shelf chiller to a specialized low-temperature system for your frozen food processing applications, this article is for you. We’ll uncover the top three advantages of making the switch.

Low-temperature chillers are more advantageous than off-the-shelf alternatives because they offer:

- Rapid pull-down capabilities

- Oil management capabilities

- Efficient evaporators for low-temperature fluid

Continue reading for more information on how you can benefit from each of these low-temperature chilling options for frozen food applications.

Rapid pull-down capabilities

Low-temperature applications often have large pull-downs, and frozen food processing is no different. However, many food processing chiller manufacturers only design for the final temperature considerations, not the entire range. This oversight compromises the system’s operation, making it highly inefficient.

Specially designed low-temperature chillers are different because they allow for quick and efficient pull-downs through the entire temperature range. Customized low-temperature options, such as electronic expansion valves (EEVs), also enhance pull-down performance, giving you tight superheat control without human interaction.

Oil management capabilities

Oil is necessary for a food processing chiller to operate, but sometimes this essential element can wreak havoc on the system if not managed effectively. The inability to deliver full oil returns to the compressor without requiring a service technician is one of the costliest drawbacks of an off-the-shelf chiller, reducing performance and efficiency and driving up operational and maintenance costs.

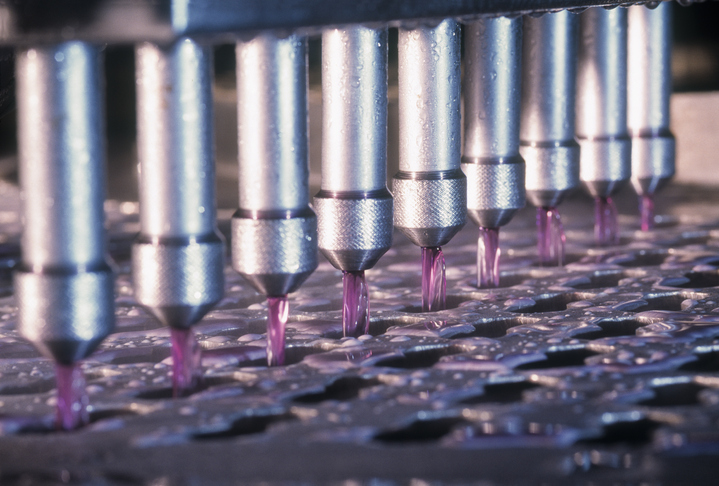

However, a specialized low-temperature chiller ensures the proper oil content remains in the compressor – where it should be. Food processing chillers contain intelligent oil management systems that include an oil separator, oil filter, solenoid valve, ball valves, and oil pressure sensor to protect the compressor, save costs, and enhance the system’s longevity.

Efficient evaporators for low-temperature fluid

At low temperatures, many standard antifreeze fluids become too viscous for off-the-shelf food processing chillers to pump, forcing you to de-rate your system’s performance. Low-temperature food chillers also have an advantage in this area because they’re designed to meet your specific fluid. By factoring in fluid properties, your food processing chiller manufacturer can size the evaporator to enhance the unit’s performance and efficiency.

Low-temperature chiller design options

When designing a low-temperature chiller to replace your off-the-shelf unit, consider the following optional upgrades to suit your specific frozen food application:

- Evaporators and heat exchangers sized for specific fluid for each application

- Electronic expansion valves (EEVs) for tight superheat control

- 1″ insulation for heat gain resistance

- Designs for fluid temperature pull-down from higher temperatures

- Compressor protection with oil management capabilities

- Compressor cooling with liquid injection and compressor fans

- Pump selection specific to fluid type

We have over 50 years of expertise in designing and engineering low-temperature chillers for frozen food processing and other specialty applications. Our ingenuity, affordability, short lead times, proven 99.4% uptime rate, and exceptional after-the-sale support make us an industry-leading source for high-performance industrial chillers. Our robust lineup of engineered solutions is proudly manufactured in the USA in Bensalem, PA, with many in-stock and custom-ready systems available for quick shipment.

Let our team show you why Drake is the premier choice for low-temperature and other high-performance chillers for any industrial application. Request a quote for your low-temperature chiller today.