When used in industrial-grade chillers, glycol is a coolant that functions as an antifreeze for specialized refrigeration and cooling systems. As opposed to ice or water only, a glycol chiller is especially useful for food processing applications, such as yogurt, ice cream, chocolate, and cold tables for salad bars and buffets. However, they’re also helpful in other environments, including breweries and dairy operations. The advantage lies in glycol’s ability to produce precise and consistent temperatures for optimal performance and efficiency.

Not all glycol chillers use the same type of glycol, and it’s important to consider your application before deciding. If you’re looking for a glycol chiller for food processing, there’s only one safe glycol choice. Keep reading to discover the type of glycol chiller you need to ensure optimal performance and food safety.

Ethylene glycol vs. propylene glycol chillers

There are two primary types of glycol that can be used in industrial process chillers: ethylene and propylene. However, only one of them is considered safe for food processing applications.

Ethylene glycol

A colorless and oily liquid with a mild odor, ethylene glycol is often used to formulate antifreeze for vehicle cooling systems and brake fluid. Beyond the automotive application, ethylene glycol is also commonly used to manufacture certain human-made fibers and low-freezing explosives, such as dynamite. Because it contains mildly toxic properties, ethylene glycol, and its derivatives, are generally not well suited for food processing chillers.

Propylene glycol

While propylene glycol contains some physical property similarities to ethylene glycol, polypropylene glycol is non-toxic, making it safe to use in food processing chillers. Additional applications for propylene glycol include cosmetics and a solvent, preservative, and moisture-retaining agent for oral hygiene products.

While there are other types of glycol, they are not designed for industrial chillers. Instead, they’re used in resin plasticizers, polyurethane, insect repellents, and tranquilizers.

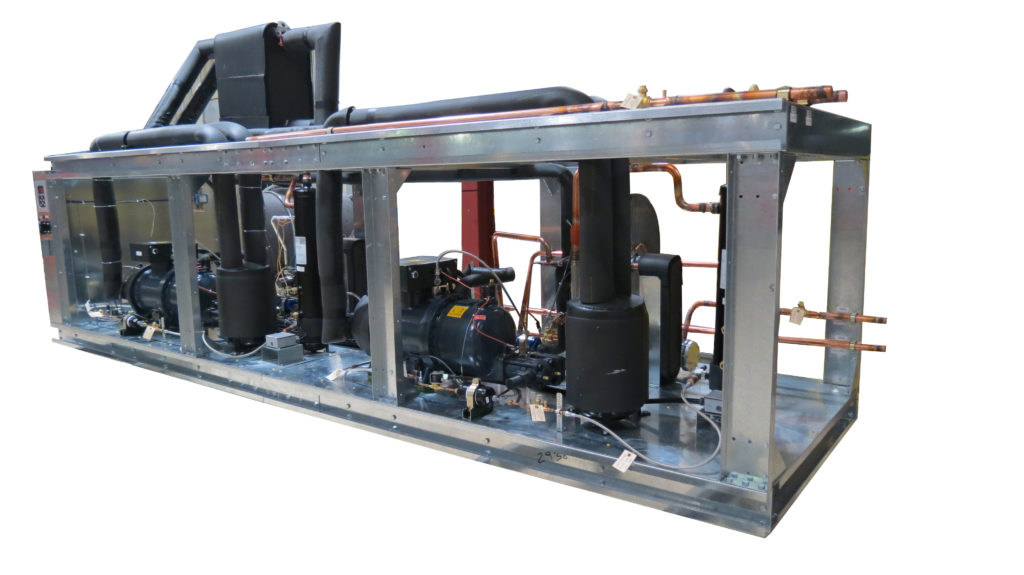

How a glycol chiller works

The glycol chiller cooling process starts when a glycol-water coolant mixture from the refrigeration unit funnels through thermal heat exchanger piping. This chilled fluid then absorbs the heat from your food processing, which warms the coolant. The now warm fluid returns to the refrigeration unit to repeat the cooling process.

Check out our blog to learn more about how process chillers work and meet the main components of a process chiller.

Benefits of glycol chillers for food processing

As opposed to using ice or other methods to cool your food process, consider the following advantages to switching to a glycol chiller:

- No product spoilage – With consistent cooling temperatures, delicate foods like ice cream and yogurt remain safe for consumers to eat.

- Improved food quality – Food chilled in a glycol cooling system often tastes better, resulting in a higher-quality product delivered to your customers’ table.

- Standard and low-temperature applications – Glycol chillers can effortlessly and continuously meet temperature requirements either above or below freezing.

- Narrow temperature ranges – A glycol chiller helps keep your food products within a specified temperature range, no matter how narrow.

- Consistent and reliable chiller performance – Because glycol doesn’t freeze, these chillers often lend more reliability than the alternatives.

Many food processing companies also run into the challenge of ice forming in the chiller, which can interfere with circulation and reduce the chiller’s performance. The glycol in glycol chillers won’t freeze, which solves ice issues – and helps save money on ice!

What to look for in a glycol chiller

- Affordable engineered solutions that meet your specific application requirements

- Precise and consistent temperature control

- Dependable performance that will last year after year

- Options for redundancy, controls, and energy-efficiency

- Short lead time

To learn more about whether a glycol chiller is right for your food processing application, request a quote online, email us, or call (888) 289-7299 today.