Water-cooled Condensers may be best known for their quick and hassle-free installation, long-lasting performance, quiet operation, and energy efficiency. They’re an ideal solution for many industrial process cooling applications, such as medical manufacturing, brewing, dairy production, food processing, and others. The secret behind a water-cooled condenser’s winning combination of benefits partially lies in the condenser’s inner workings. These units feature a highly efficient water-cooled design that functions as a specialized heat exchanger to condense hot, high-pressure gas from the compressor down to a liquid.

There are three primary types of condensers in Water-Cooled Condenser chillers, each designed to keep your processes cool and running strong:

- Shell-and-tube

- Brazed plate

- Coaxial tube-in-tube

Water-Cooled Condensers #1: Shell-and-tube

Overview: Shell-and-tube is one of the most common types of water-cooled condensers. This efficient heat exchanger is easy to clean and repair, contributing to a hard-working and cost-effective water-cooled chiller.

Design and operation: The construction materials of a shell-and-tube condenser often include a carbon or stainless-steel shell with welded grooved end plates and straight copper water tubes positioned for a vapor-tight fit. During operation, the compressor releases hot refrigerant into the shell. At the same time, water flows through the tubes, leaving the refrigerant inside the shell. Once the water-cooled chiller’s refrigerant hits the water tubes, the vapor begins its liquid conversion before releasing the newly condensed liquid refrigerant through the cylindrical shell, where it will make its journey to the expansion valve.

Pros:

- Easy to clean

- Easy to locate and plug tube leaks

- Ideal for pump-down and low ambient environments

- Thick tube walls for rugged mechanical construction

- Lower probability of fouling and scaling

- Less susceptible to freeze damage

Cons:

- May not be suitable for applications with limited space

- More expensive than brazed plate water-cooled condensers

- Greater surface area can reduce thermal efficiency

Water-Cooled Condensers #2: Brazed plate

Overview: Brazed plate is another type of water-cooled condenser you’ll find in packaged water-cooled chillers. It’s best known for its cost-effectiveness and corrosion-resistant and enhanced heat transfer properties.

Design and operation: Brazed plate water-cooled condensers feature a non-ferrous construction that resists rusting and corrosion. Alternating metal plates are held together with a copper-based brazing material and feature an embossed pattern to create a fluid channel. During a water-cooled chiller’s operation, cold fluid makes contact with one side of the plates and not the other. This water-cooled design helps generate highly efficient heat transfer between process and refrigerant fluids.

Pros:

- Compact design is ideal for limited space environments

- Non-ferrous construction resists corrosion and rust

- Enhanced heat transfer, thanks to the small passages that encourage a turbulent flow

- Economical and cost-effective

Cons:

- Small passages can cause elevated water side pressure drops

- Small passages are susceptible to plugging and fouling

- Brazing material is subject to corrosion

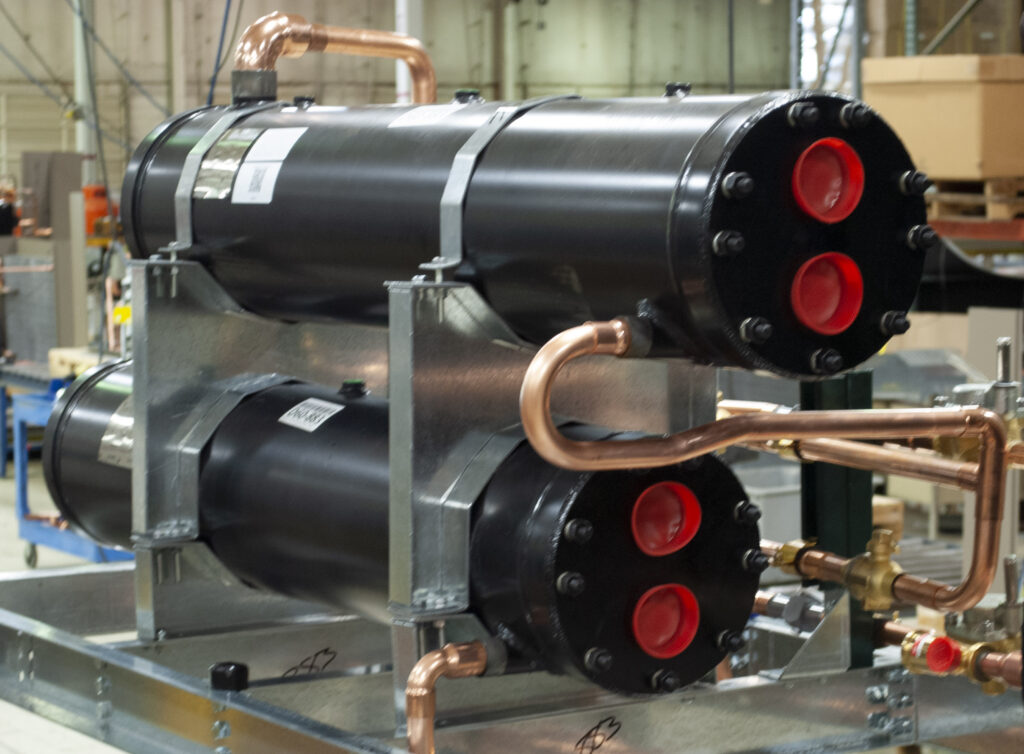

Water-Cooled Condensers #3: Coaxial tube-in-tube

Overview: Coaxial tube-in-tube is the third type of condenser in a water-cooled chiller. It earns its name because the tubes are coiled around the same axis. Excellent anti-fouling characteristics make these high-performance and compact heat exchangers stand out from other condenser types.

Design and operation: Coaxial tube-in-tube water-cooled condensers use two nested tubes to achieve a counter-flow design, where water flows in the opposite, or “counter,” direction to the refrigerant. During operation, fluid passes through the inside tube while simultaneously cooling the refrigerant in the outer tube. It’s designed so that the coldest water makes contact with the coldest water-cooled chiller refrigerant to generate the highest mean temperature differential and heat transfer rate.

Pros:

- Highly effective operation

- Compact design

- Excellent anti-fouling characteristics

- Ideal for high temperature, high pressure, and low-flow applications

Cons:

- Can be cost more than other water-cooled condensers

- It’s not feasible to clean the water side, making chemical cleaning the only solution should fouling occur

- May not be suitable for large industrial process cooling applications

Which water-cooled condenser is right for your water-cooled chiller? Contact our industrial process cooling experts online or call (888) 289-7299 to learn more about our robust engineered solutions designed for your specific application.